With only a little less than a month left in the year, which means you’ve probably been working hard on your fire and life safety plan for the New Year. One service that should be included is Arc Flash Assessments. So how can an Arc Flash Assessment help keep your building in compliance and your workers safe?

With only a little less than a month left in the year, which means you’ve probably been working hard on your fire and life safety plan for the New Year. One service that should be included is Arc Flash Assessments. So how can an Arc Flash Assessment help keep your building in compliance and your workers safe?

As you may already know, an arc flash is an intense release of injury caused by an electrical arc fault between two conductors. The flash and ensuing blast result in a violent explosion that contains intense heat and energy. A typical arc flash incident can be minor but could easily produce a more severe explosion. Not to mention, the results of an Arc Flash are devastating to both the equipment and workers. The destruction of equipment during an arc flash can result in expensive replacement costs and downtime. Severe burns are the most common injury to electrical workers and likely will result in permanent damage such as blindness, hearing and internal injuries from the blast. This is why an Arc Flash Assessment is an essential part of a compliant electrical safety program.

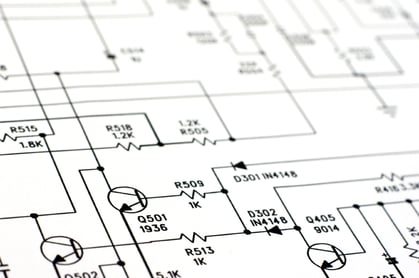

An Arc Flash Assessment is an engineering study of the electrical distribution system that is designed to identify the degree of hazard inside each electrical device. By identifying the degree of hazard and boundary distances, it allows the worker to choose the appropriate Personal Protective Equipment (PPE). Therefore, OSHA requires that employers identify electrical hazards (including Arc Flash) and protect their workers from these hazards. NFPA provides guidance on how to keep your workers safe, with NFPA 70E, which requires an Arc Flash Assessment that includes Energy Calculations & Arc Flash Labels that identify PPE and must be performed at a minimum of every 5 years.

Arc Flash Assessments – 5 Steps to Compliance:

- Collection of Data (One line Drawings)

Save time and money with improved response time through updated drawings and inventory.

- Calculations of Incident Energy

Identifying hazards, such as incident energy will tell you the level of risk in your electrical panels.

- Coordination Study & Mitigation

Reduce the risk by lowering the incident energy and hazard risk category. This will help lower your personal protection equipment (PPE) requirements.

- Arc Flash Labels

Ensure compliance with OSHA and NFPA 70E. Arc Flash Risk Assessments that include incident energy calculations and arc flash labels are required for compliance.

- Arc Flash Training

Learn to work safely within your electrical environment, by gaining awareness and saving lives.