It’s true—we’re spending more time at our workplace. It’s estimated that within a typical 50-year period of employment, the American worker will spend over 13 years of his/her life on the job. If you’re an employer, a clean and safe place is vital for your employees’ well-being. It’s also the law (1).

Know the Risks

Keeping a facility OSHA-compliant is a step in the right direction of being incident-free. It’s also important to understand the risks associated with your specific industry. A paper plant will have a higher risk of combustible dust, while a BioMed facility’s risks will likely involve biological or chemical agents.

However, guard against the mentality that if it’s never happened before, it will never happen. False beliefs about existing workplace hazards prevent companies from taking steps to mitigate them. The result? Dangerous incidents resulting in injury or death that could have been prevented.

OSHA Violations & Recent Citations

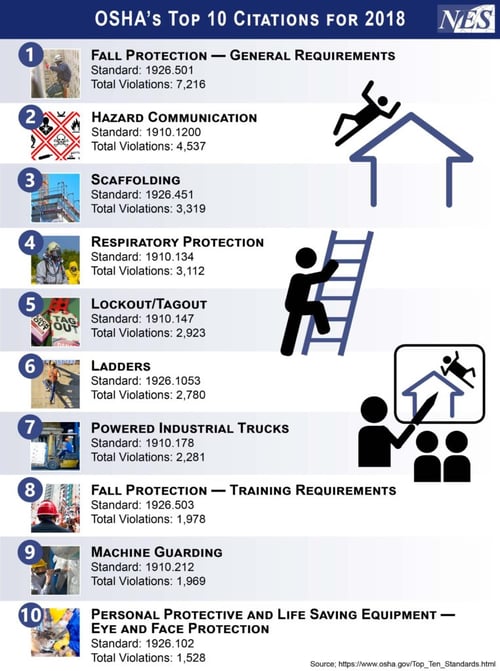

Last October, the Occupational Safety & Health Administration (OSHA) released its list of top-ten violations cited in 2018.

Though not listed above, failure to control dust and ignition systems continued to be a stand-out violation in 2018, one that resulted in substantial fines.

A corn milling facility was placed under OSHA’s Severe Violator Enforcement Program after it was cited for 14 violations, with fines in excess of $1.8 million. This came after an investigation of the plant’s May 2017 explosion that killed five workers and injured 12 others. The source of the explosion? An accumulation of highly combustible dust paired with uncontrolled ignition sources.

In February this year, a paper products manufacturer in Mississippi was cited for several violations, including “allowing combustible dust to accumulate on surfaces.” The manufacturer faces over $300,000 in penalties for “putting workers at serious risk of injury or death.” (2)

Facts About Combustible Dust

You may think the dust created in your facility is not combustible. Consider 3D printing, which is used in a variety of industry-types. Not only are the materials used combustible, but the printing process itself generates a very fine dust. The fact: any dust created from plastics, rubbers, coal, fossil fuels, sugars, grains, food, paper, textiles, and metals are combustible. Over a period of time, residues and dust particles accumulate and create a life-threatening fire hazard.

NFPA 654 (Standard for the Prevention of Fire and Dust Explosions from the manufacturing, Processing, and Handling of Combustible Particulate Solids) includes procedures to reduce and manage dust. One of those procedures is a regular inspection and cleaning, conducted at regular intervals. The mitigation should be done by OSHA-certified and trained professionals, using equipment that is grounded to provide a spark-free operation.

After regular inspections and cleaning are established, an arc flash assessment is advisable as well. An arc flash (when a flash-over of electrical current leaves its intended path) is extremely dangerous, with its powerful electrical explosion and extreme temperature (can reach over 35,000 degrees Fahrenheit). When there is a build-up of dust, the combination could be disastrous.

Adhering to OSHA standards to mitigate combustible dust or any other potential hazard does not guarantee an incident-free workplace. But it will ensure your facility is as safe as possible for your company’s most valuable asset—your employees.

In OSHA’s Combustible Dust National Emphasis Program, two of the most common citations were improper housekeeping, including combustible dust accumulation, and use of compressed air to blow down combustible dust. Hughes Environmental abides by standards set by the NFPA, NADCA, and OSHA when performing combustible dust cleaning. Hughes Environmental technicians are trained in OSHA’s 10 or 30-hour Safety, Aerial Lifts, Confined Spaces, First Aid, CPR, and Combustible Dust Safety and Awareness.

To schedule an inspection or service, send a request to Hughes Environmental or call: 888-845-3952.

Contributing source and Illustration credit: https://www.nesglobal.net/oshas-top-10-list-of-citations-for-2018/

(1) Under the Occupational Safety and Health Act of 1970, employers are responsible for providing safe and healthful workplaces for their employees.

(2) According to the OSHA news release from Feb. 20, 2019;https://www.osha.gov/news/newsreleases/region4/02202019