Imagine trying to clean 150 years of marine corrosion off of a warship using only dental picks. This tedious, time consuming work is exactly what conservators restoring the USS Monitor were dealing with. That is, until sample tests showed that dry ice blasting can be used successfully to clean the corrosion from the cast iron warship.

Now, restoration projects on the USS Monitor can be completed within minutes, instead of the months it would have taken by hand cleaning. The Senior Conservator William Hoffman expressed excitement at the new cleaning method by saying, “It could mean a dramatic difference in the amount of time it takes to treat the turret and put it on exhibit. We don’t know exactly how much time it will save, but we could be talking about accelerating the process by years.”

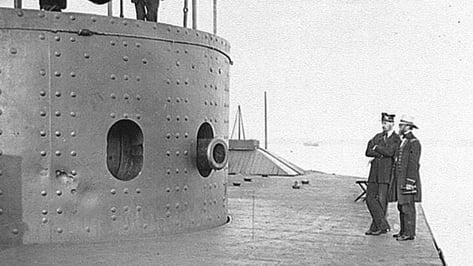

The USS Monitor was the first ironclad warship built for the Union Navy during the Civil War, and is most famous for the Battle of Hampton Roads on March 9, 1862, where it fought the ironclad warship CSS Virginia. This battle was the first battle between armored warships, and even though the four hour battle ended in a standoff it changed naval warfare forever.

After fighting in the Battle of Drewry’s Bluff the USS Monitor headed towards a blockade off North Carolina, but sank during a storm off Cape Hatteras. In 1973 the wreck of the USS Monitor was discovered and partially salvaged.

The conservators wanted to be absolutely sure that dry ice cleaning would work on the corroded cast iron without causing any additional damage, and after two years of tests it was finally approved for use on larger scale cleaning of the warship. Hoffman explained that “even when the surface was magnified 350 times, we didn’t see any pitting. We didn’t see any signs of abrasion. We didn’t see any damage.”

The salvaged pieces of the warship will go through alternating cycles of dry ice blasting and treatment in electrolytic reduction tanks to completely and safely remove the corrosion from the iron.